FLEXCO® BOLT SOLID PLATE Fastening System

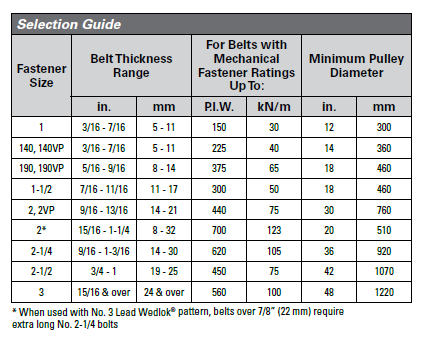

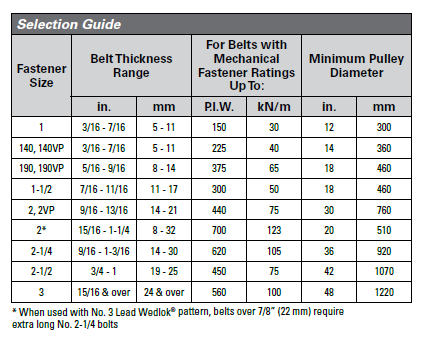

Flexco® Bolt Solid Plate fasteners are engineered to meet the demands of the toughest material handling applications,

providing a strong, sift-free splice with superior holding ability. A choice of sizes accommodates belts from 3/16” (5 mm) to over 15/16” (24 mm) thick.

High strength

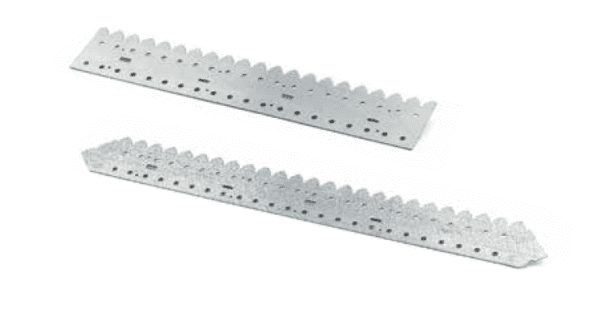

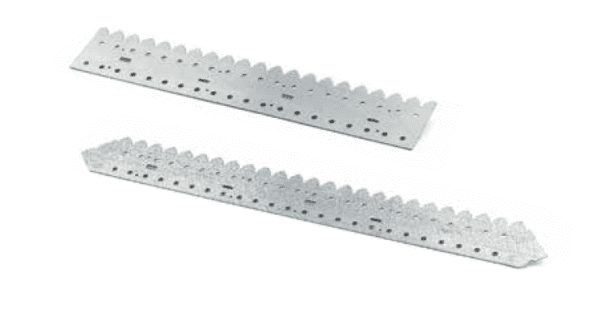

High strength is the result of superior design and plate compression on both the top and bottom sides of the belt. High tensile strength bolts compress top and bottom plates to distribute splice tension evenly across the entire width of each fastener plate. For added strength and pullout resistance, specially formed teeth penetrate deep into the belt carcass – without damaging carcass fibers.

Easy installation

Field-proven templets, punches, and boring tools make it easy to quickly and accurately prepare belts for fastener installation. Fasteners are easily installed on-site using portable hand tools or power tools. Our exclusive piloted bolts also contribute to faster installation.

Market applications

Sand • Gravel • Crushed Stone • Grain • Coal • Cement • Salt

Fasteners

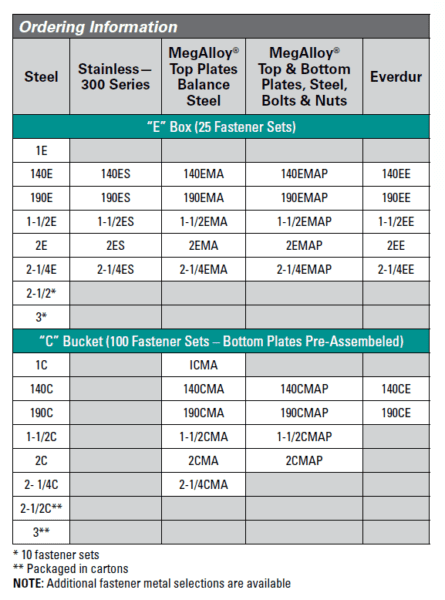

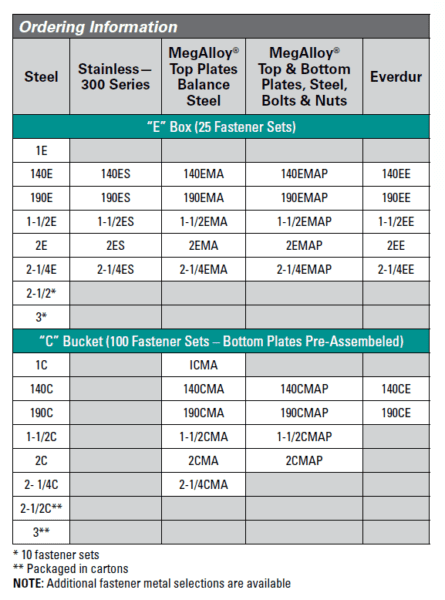

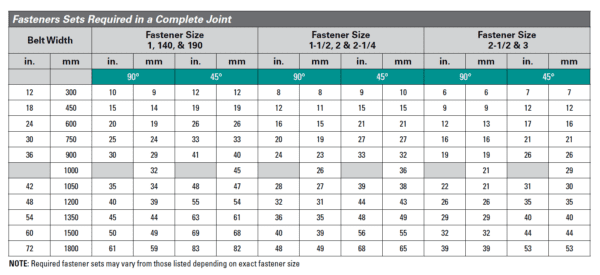

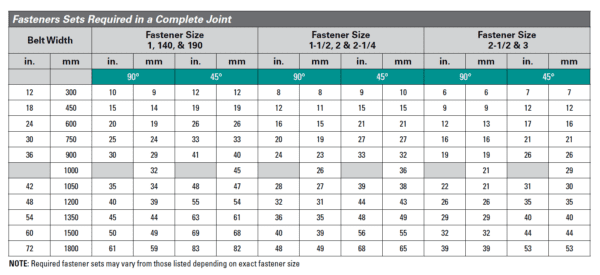

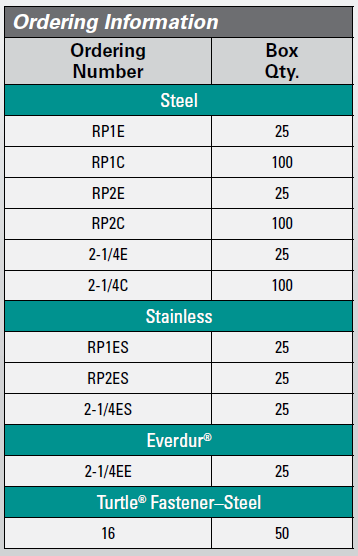

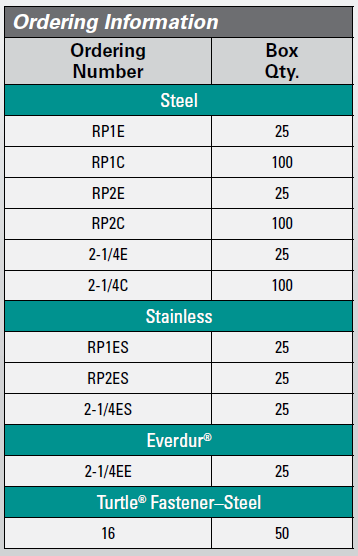

Each Quick-Fit “E” box contains 25 complete fastener sets. A set consists of a top plate, a bottom plate, two nuts, and two bolts.

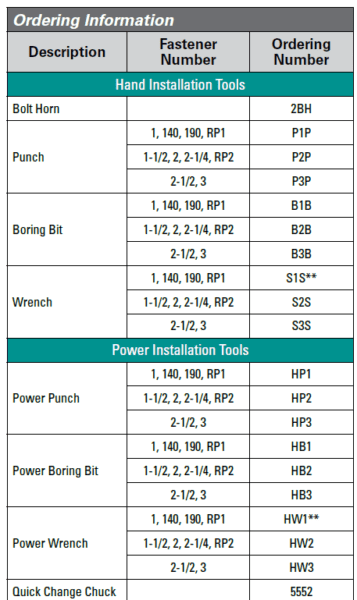

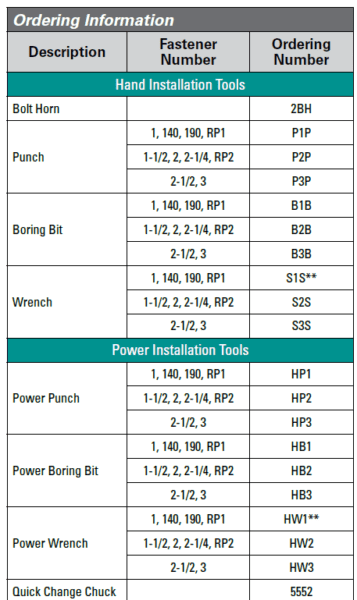

Installation Tools

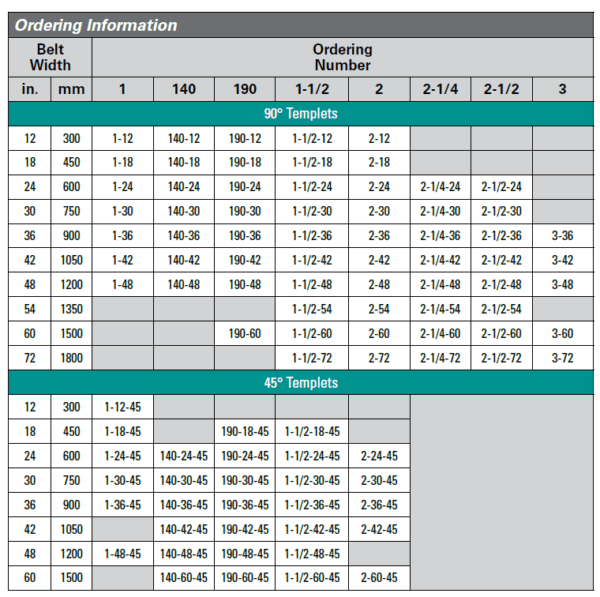

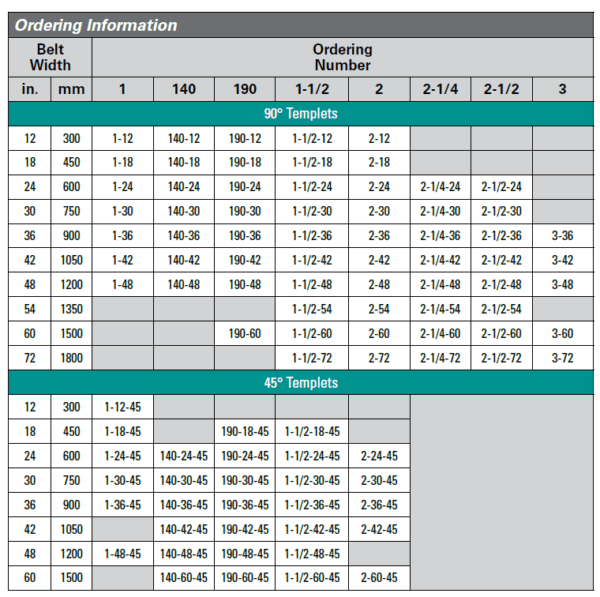

90º and 45º Templets

Templets are required for 90˚ and 45˚ Bolt Solid Plate fastener installation. Templets simplify installation by providing a guide for accurate bolt-hole placement. Lengths for all standard belt widths are available.

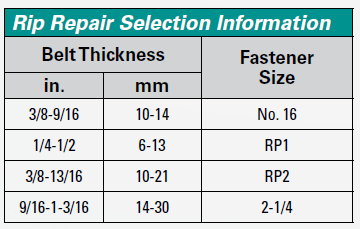

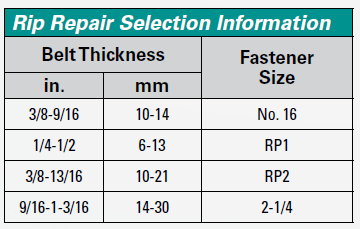

Rip Repair

Use standard Flexco® Solid Plate fasteners to repair conveyor belt holes and edge tears. For jagged length-wise conveyor belt tears, standard Bolt Solid Plate fasteners can be combined with three-bolt Rip Repair fasteners. Three-bolt Rip Repair fasteners can also be used to bridge “soft” spots in the belt before they become rips.

Installation Tools and Supplies

The only tools needed for Bolt Solid Plate fastener installation are a templet and portable hand or power tools such as wrenches and belt punches. Impact wrench driven power tools are recommended and can reduce installation time by at least 50%.

Flexco-Lok® Tape

Rigid nylon tape helps eliminate belt ripples on plied or solid-woven belting so belts run smoothly over pulleys and under cleaners. Also helps seal splices against seepage of fines and moisture.

Cracking Chisel

With a hammer and cracking chisel, individual worn plates can be easily replaced – without resorting to replacement of the entire splice.