Hydraulic Hose, Fittings, Couplings & Accessories

RGA Aeroquip Express Stores

We make hydraulic hoses while you wait!

With Aeroquip products from Danfoss, you have world-class quality and innovation working for you. With wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities, Danfoss hose and tubing products provide the ultimate fluid conveyance solutions for a variety of equipment and applications.

Need a replacement hose fast? Visit one of our Aeroquip Hose Centers in Arkansas, Alabama, Indiana, Kentucky, Mississippi, Missouri, Ohio, Oklahoma, Tennessee, and Texas.

Choose a Provider Who Has Everything You Need

RGA IS AVAILABLE 24 HOURS A DAY, 365 DAYS A YEAR.

From crimp and reusable fittings, quick disconnect couplings to steel adapters and more, RGA delivers an incredible range of fittings and connectors for virtually any application to help you make the right connection every time. We can provide the hose and fittings that meet global performance standards, right when you need them. We include a broad selection of hydraulic assembly equipment, andwe can also produce a high-quality, reliable hydraulic hose assembly while you wait.

- Sae & Din Spec

- Rubber Braided, Spiral, & Thermoplastic Braided Hose

- Imperial & Metric Fittings

- Permanent Crimp & Field Attachable Fittings

- Imperial & Metric Adapters

- Quick Connects

- Crimper & Saw On-Site Placements

The Fabulous Five

NORTH AMERICA’S MOST POPULAR QUICK COUPLINGS

Across North America, there are five popular quick coupling styles that serve a wide variety of mobile and industrial applications.

DF Series

- Interchangeable with Parker 20/30-Series and other MIL-C-4109F/ISO6150B couplings

- Automatic couplers have a reverse-acting sleeve for easy connection and safe one-handed disconnection

- Manual couplers have a sleek profile, with sleeve-guard lip to prevent accidental disconnection

- Available in steel, brass, and 303 stainless steel

- Available in sizes 1/4" to 3/4"

H Series

- Interchangeable with Parker 60-Series, Danfoss/Hansen HK-Series, and Faster HNV-Series

- Standardized product variations available to meet the requirements of slide-gate, food service, and steam applications

- Meets or exceeds ISO7241 Series 'B' performance requirements

- Wide variety of material choices, including: steel, brass, 303 stainless steel, and 316 stainless steel

- Available in sizes 1/8" to 2-1/2"

K Series

- Interchangeable with Parker 6600-Series, Faster ANV-Series, and Danfoss 5600

- Meets or exceeds ISO7241 Series 'A' performance requirements

- Rugged steel construction and Trivalent Chrome plating will maximize durability and service life

- Available in sizes 1/4" to 2"

HT Series

- Interchangeable with Parker FEM-Series, Stucchi FIRG/Series A, and Faster FFH-Series

- Meets or exceeds ISO16028 performance requirements

- Drybreak design prevents spillage upon disconnection and air inclusion during connection

- Material choices include steel or 316 stainless steel

- Available in sizes 1/4" to 2"

W Series

- Interchangeable with Parker 6100-Series, and Danfoss 5100

- Drybreak design significantly minimizes spillage/air inclusion during connection/disconnection

- O-ring full-connection indicator will remain highly visible, despite operation in dirty environments, allowing operators to ensure the parts are fully connected, maximizing the performance of their systems

- Brass construction ensures optimum corrosion resistance, while the high tensile steel components resist failure associated with pressurizedflow connection/disconnection and surge flow conditions

- Innovative hybrid valve guide design provides industry leading flow and pressure performance

- Full hex on both coupling halves for easy installation

Quick Coupling Selection Guide

1. Determine the profile (shape) of the plug using the chart below to determine if it is pneumatic or hydraulic:

Hydraulic

Pneumatic

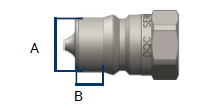

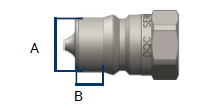

2. Body size dimension charts can be found within each series section. Measure the A (diameter) and B (tip length) dimensions to determine the plug body size.

3. Use the industry standard thread chart below to determine the end connection thread size. If you have a hose barb, the ID measurement of your hose will determine the barb size (figure 2).