Sheet Material

- Non-Asbestos

- Ptfe

- Neoprene

- Epdm

- Nitrile

- Red Rubber

- Gum Rubber

- Viton

- Silicone

- Uhmw

- Urethane

- Nylon

- Pvc

- Hdpe

- Lexan

- Non-Asbestos

- Ptfe

- Neoprene

- Epdm

- Nitrile

- Red Rubber

- Gum Rubber

- Viton

- Silicone

- Uhmw

- Urethane

- Nylon

- Pvc

- Hdpe

- Lexan

We stock sheet materials, and we can cut them into custom parts with your specifications. While some materials are still cut by hand, we've added both flash cutting and waterjet cutting systems to guarantee quality, reliability and performance.

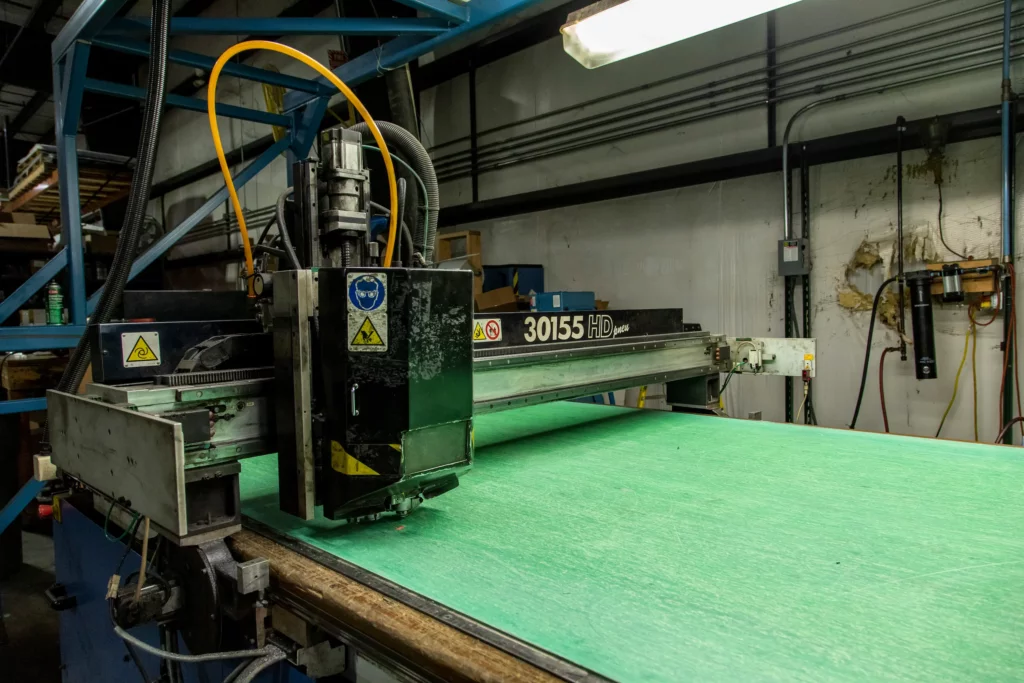

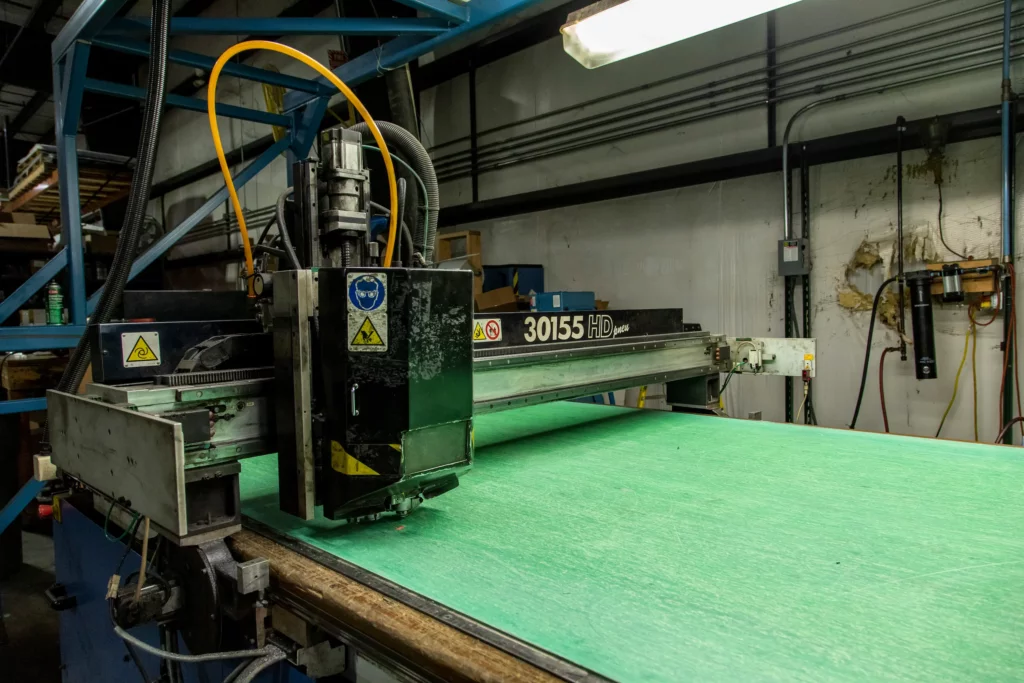

What is Flash Cutting?

Flashcutting creates custom parts in minutes. It is a dieless knife cutting table used for cutting soft and semi-rigid materials. It uses an oscillating knife CNC cutter that operates on AutoCAD files. This means large and complex gaskets can easily be inputted and stored for repeatability. Flash cutting also reduces material waste with nesting software that increases yield and lowers the costs of parts.

What is Waterjet Cutting?

Waterjet cutting isn’t actually cutting; it’s technically eroding. An intensifier uses 3000 PSI of hydraulic pressure to 60,000 PSI water pressure to move water to the cutting head, where it is forced through a jewel orifice to the material. Waterjet cutting is the fastest growing machining process in the world. Acclaimed for speed, accuracy, and cost effectiveness we invite you to experience the difference for yourself.