Light Weight Conveyor Belting & Accessories

Because we supply the highest quality products, we can provide comprehensive, tailor-made solutions from our extensive range of light weight belting.

- Thermoplastic Monofilament Belt

- Thermoplastic Monolithic Belt

- Plastic Modular Belt

- Belt Fasteners & Tools

- Vulcanizing Presses

True value goes deeper than products. But at RGA we combine great products with a drive for reliability to create lasting value for our customers.

Other Critical Elements of a Good Splice:

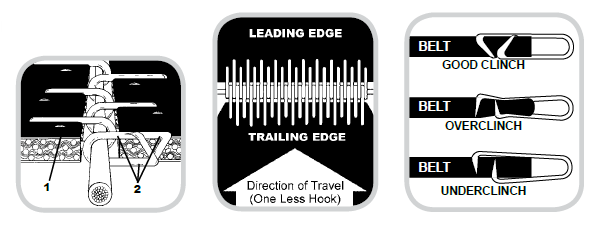

- Hook points should slightly penetrate the opposite side.

- Hook legs should be parallel when installed. The knuckles of the hooks

should not be higher than the legs. - Do not lace entire width. Leave ¼"– ½" on each edge unlaced.

- Use one more hook on leading edge than on trailing edge.

- Chamfer/notch trailing edge.

- Belt edges should line up when laced ends are connected.

Every industry is unique with special requirements and conditions that continue to change and evolve. These may range from the fulfillment of legal requirements for food contact through coping with bulky shaped goods, as well as over long and winding conveyors to high precision and wear resistance features.

Automotive and Tire

New technologies are radically changing production; selection of the right belts has become decisive for producing cars and tires efficiently and economically. Habasit offers a complete, innovative range of products and solutions. RGA supplies HabasitLINK® plastic modular and HabaFLOW® fabric based conveyor and processing belts, HabasitDRIVE® power transmission belts and gear motors for all automotive applications including press lines, punching machines, skid conveyors, and people mover belts.

Printing, paper, and postal

Printing, finishing, and paper/cardboard converting processes require a broad range of different belts. HabaFLOW® fabric based belts, HabaSYNC® timing belts, HabasitLINK® plastic modular belts as well as Habasit chains and seamless belts perfectly meet customer needs.

Wood Industry

Wood is a valued natural material that needs to undergo considerable processing. You’ll find Habasit conveyor and power transmission belts and HabasitLINK® plastic modular belts in wood plants around the world processing the raw materials to make plywood, particleboard, MDF, and OSB.