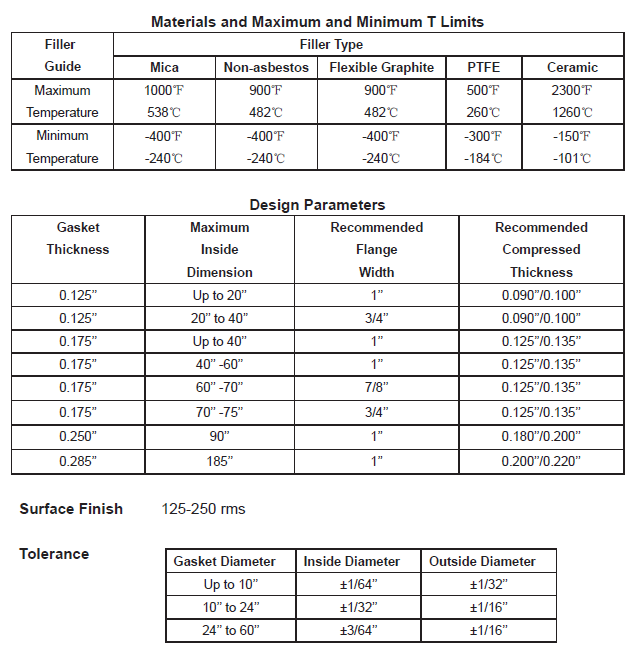

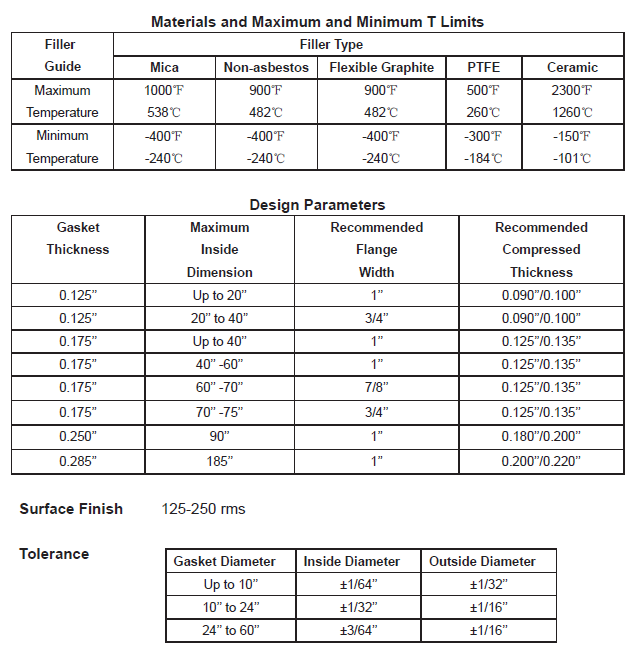

Spiral Wound Gaskets (SWG) are made with an alternating combination of an engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The SWG material including metal strip and filler material can be selected for a wide range of applications. All SWGs have been engineered to precise manufacturing tolerances that allow for lower stress (bolt load) sealing in comparison to conventional spiral wound gaskets.

Global SWGs Meet ASME B16.20 Standards, which stipulate that an inner ring is required for all PTFE filled gaskets and for all class 900, 1500 and 2500 class gaskets. Quality Assurance complies to API Specification Q1 and ISO 9001:2000.

Global SWGs Exceed Customer Expectations. For example, style 6000OR and 6000IOR carbon steel centering rings are zinc electroplated providing superior corrosion resistance. Zinc electroplating (silver color) also makes it easier to identify gaskets since it does not fill in the identification mark. 6000OR SWGs and gaskets 6000IOR SWGs are manufactured to meet the different types of flanges (Gaskets for non-standard flanges are also available):

- ASME B16.5

- BS 1560

- BS 10

- ASME B16.47 Series B (API 605)

- ASME B16.47 Series A (MSS SP 44)

- BS 4504

- DIN Flanges

- JIS Flanges

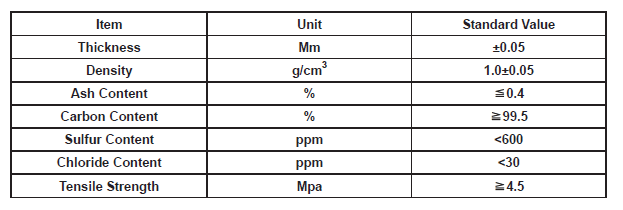

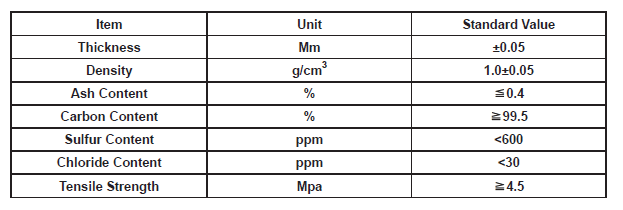

Global SWGs Use High-quality Nuclear Grade Flexible Graphite:

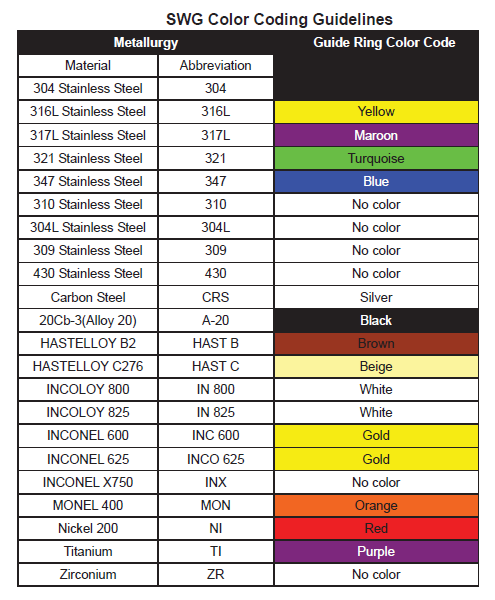

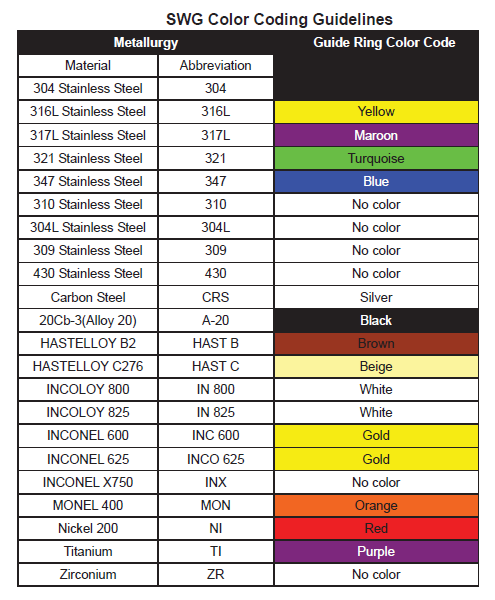

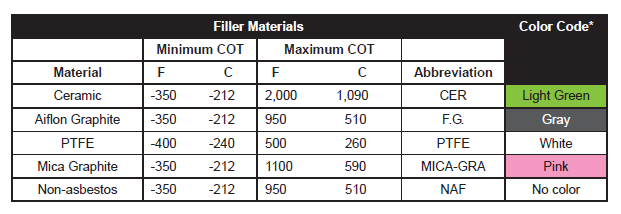

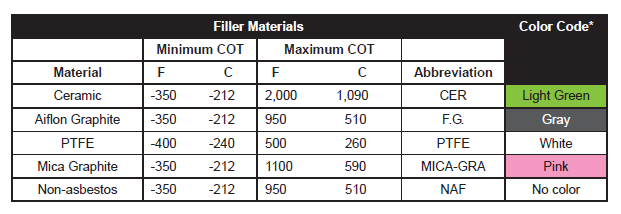

SWG Identification by Color Coding: For ease of identification, Global SWGs utilize a color coding system around the outside edge of the centering ring, thus permitting full identification of both the winding and materials.

Global SWG Style and Selection: SWG includes 6000, 6000IR, 6000OR, 6000IOR, 6000H, 6000LS, 6000S and other styles.

Style 6000OR utilizes an external ring which accurately centers gasket on flange face, providing additional radial strength to prevent gasket blowout and acts as a compression stop. This gasket is suitable for use with flat face and raised face flanges up to Class 2500 (Class 600 or above needs an internal ring).

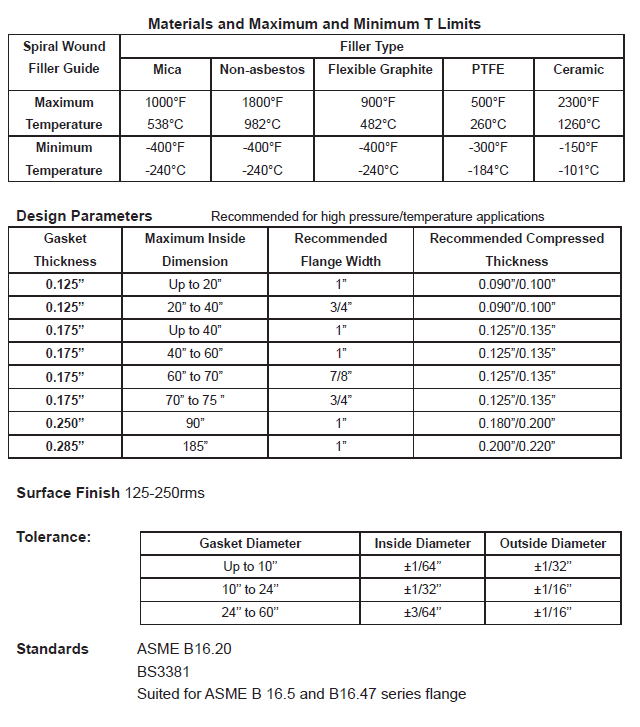

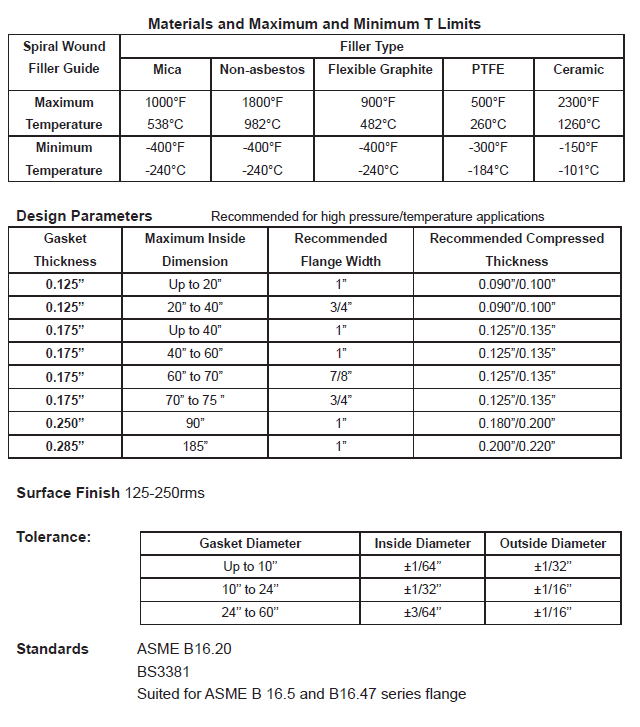

Style 6000IOR a gasket is fitted with internal ring which provides an additional compression stop and provides heat and corrosion barrier to protect gasket windings and prevent flanges from corrosion. These gaskets are suitable for use with flat face and specified for high pressure/temperature service Class 900 and above or where corrosive or toxic media are present.

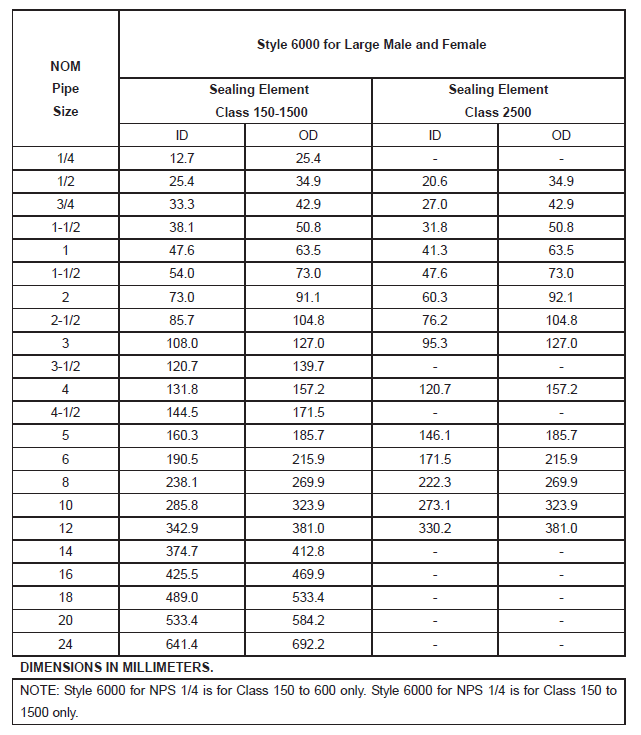

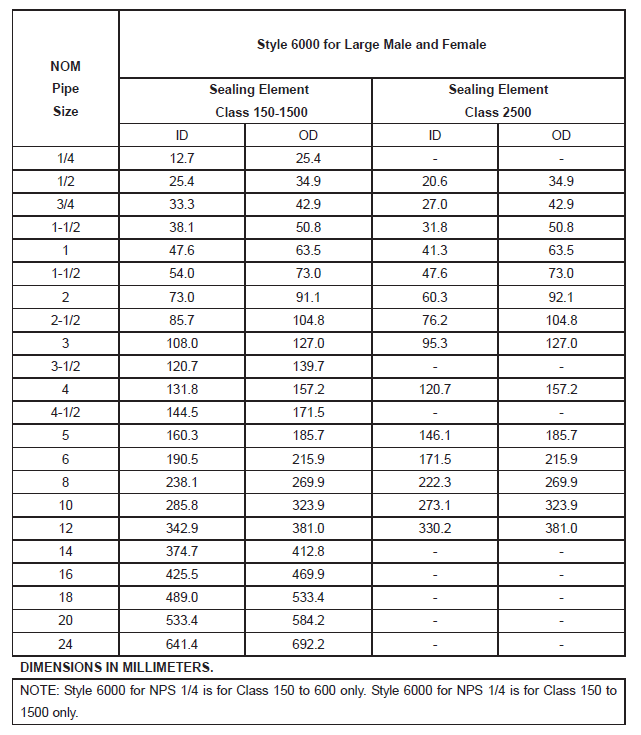

Style 6000 gaskets’ inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression and sealing characteristics. These types of gaskets are suitable for tongue and groove or male and female or grooved to flat flange assemblies.

Style 6000IR has a solid inner metal ring that acts as a compression stop and fills the annular space between flange bore and the inside diameter of the gasket. The gaskets are designed to prevent accumulation of solids, reduce turbulent flow of process fluids, and minimize corrosion at flange faces. The gaskets are suitable for male and female pipe flanges.

GLOBAL 6000 IS FOR USE WITH MALE & FEMALE AND TONGUE & GROOVE ASME B16.5 & BS 1560 FLANGES: Standard Style 6000 gaskets are manufactured to a nominal thickness of 125’’ 3.2mm. Optimum compression is in the range of .090” to 100” (2.3mm to 2.5mm) thick.

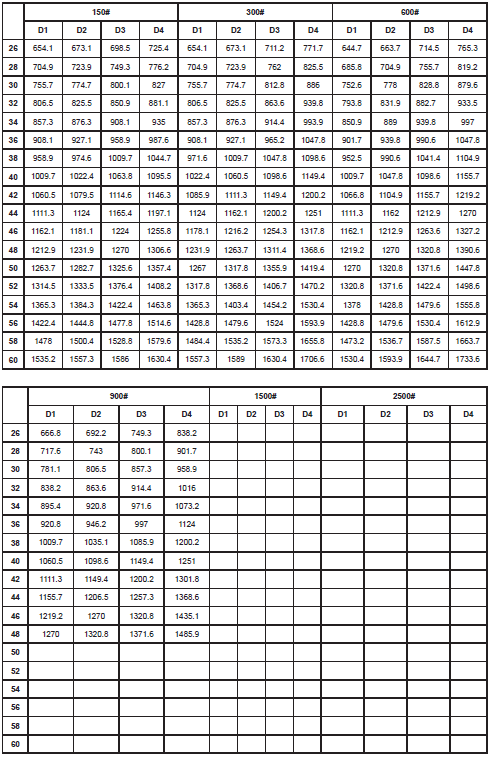

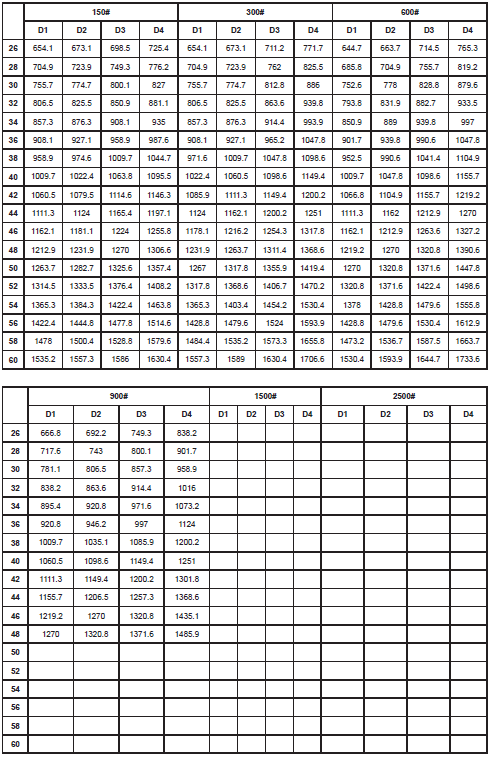

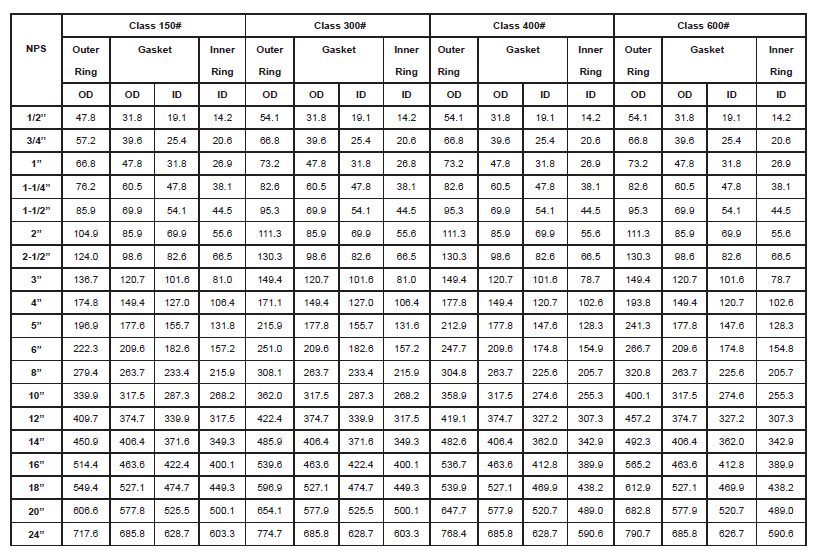

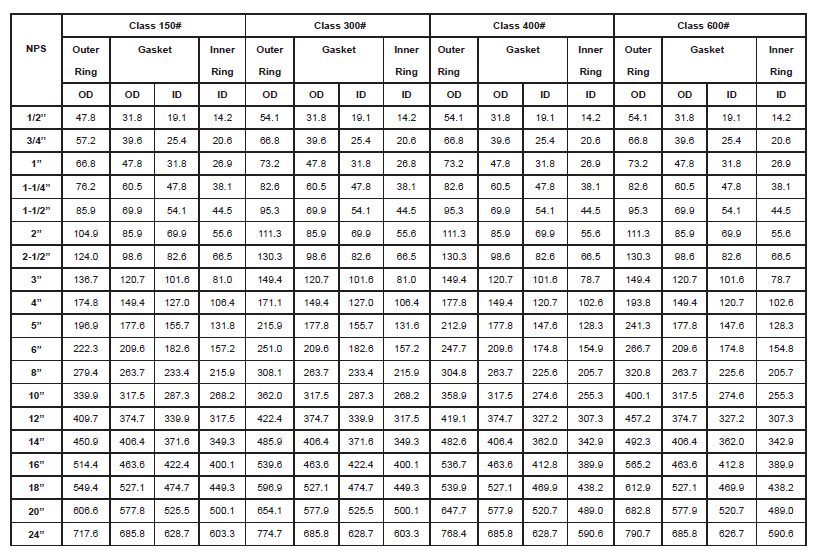

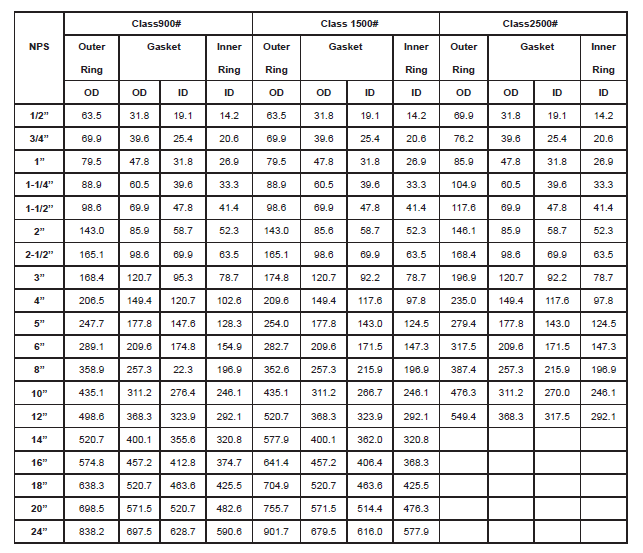

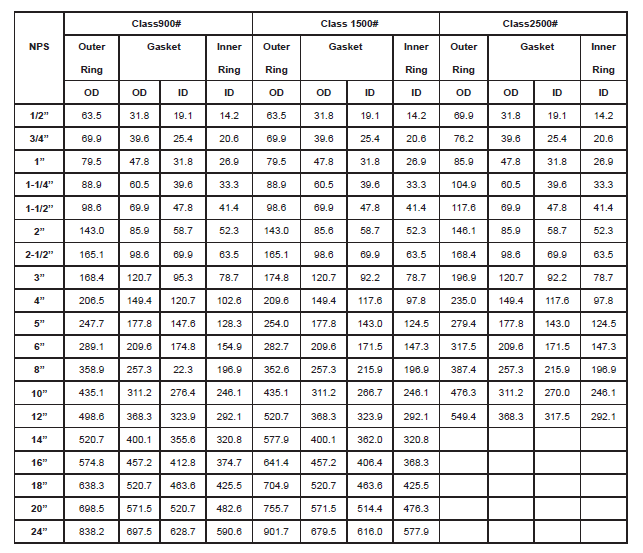

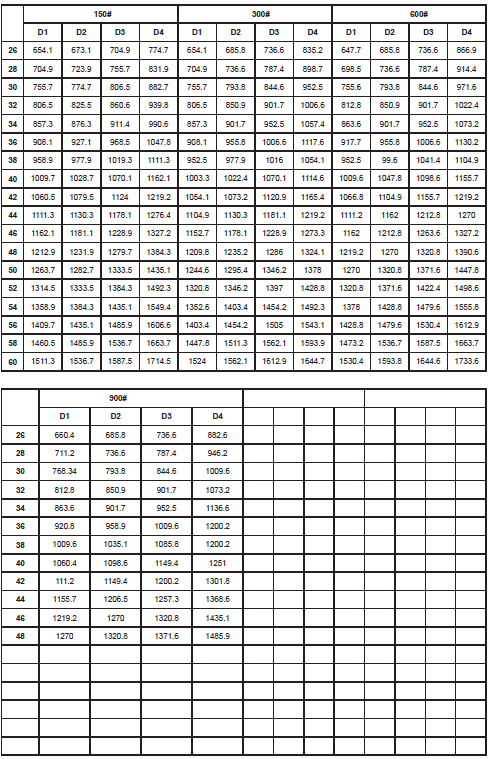

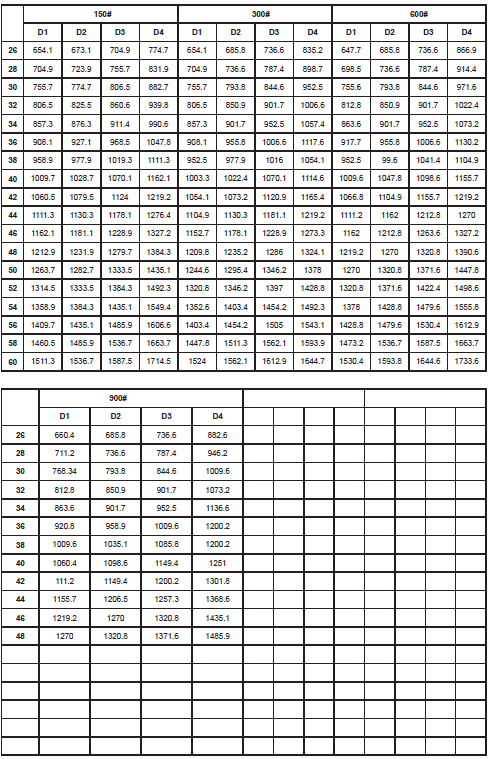

GLOBAL 6000OR IS FOR FLAT AND RAISED FACE DIAMETER FLANGES UP TO CLASS 2500.

GLOBAL 6000IOR IS USED FOR FLAT AND RAISED FACED DIAMETER FLANGES UP TO CLASS 2500.

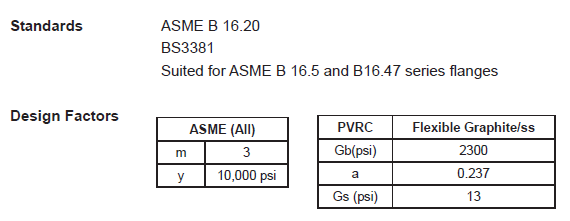

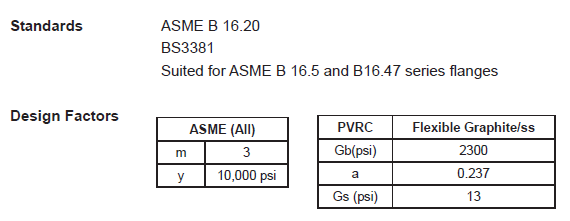

GLOBAL 6000OR & 6000IOR: ASME B16.20

ASME B16.47 Series A

ASME B16.47 Series B