SUPER-SCREW® Flexible Rubber Fastening System

The Choice Over Vulcanization

The simple and practical Super-Screw Flexible Rubber Fastening System can be used in place of vulcanization, saving you from long periods of downtime due to waiting for a crew to arrive, belt preparation, press set-up, and cooking time. It can also be used in the toughest, most demanding environments, regardless of climate and temperature, keeping your employees safer and more productive. It withstands temperatures from -22° F to 3928 F (-30° C to 200° C), making it the perfect alternative to vulcanization. This easy-to-install fastening system can be used to repair any spot on the belt, or for joining brand new belts ends, without the need for an outside service or skilled technician. The Super-Screw system is also compatible with belt cleaners, and smaller pulley diameters, and is highly abrasion resistant.

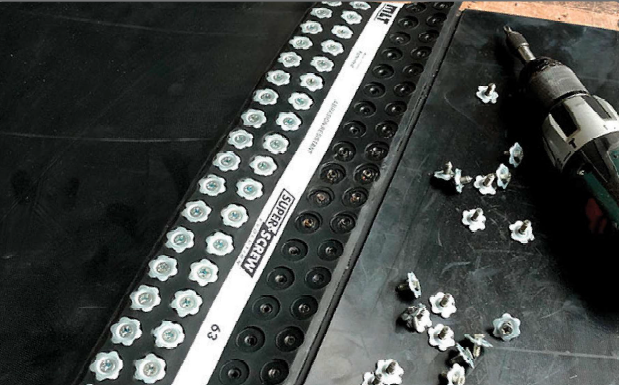

How It Works

The Super-Screw® Flexible Rubber Fastening System utilizes specially signed self-drilling, self-tapping screws that preserve the integrity the belt by passing between the carcass threads without cutting them. Super-Screw comes ready to be installed, with assembly pacers already in place, so that the top and bottom covers align correctly. Screws and Pozidrive or “PZ” bits are included for easy installation, without the need for tools beyond a standard powered drill or 1/4″ impact driver. The result is a splice that can be installed anytime, anywhere, and in any weather condition.

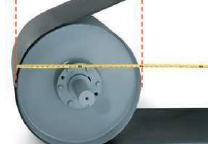

Measure smallest pulley diameter and determine the belt’s tension rating (PIW)

Measure belt thickness after skiving

Choose Super-Screw splice length

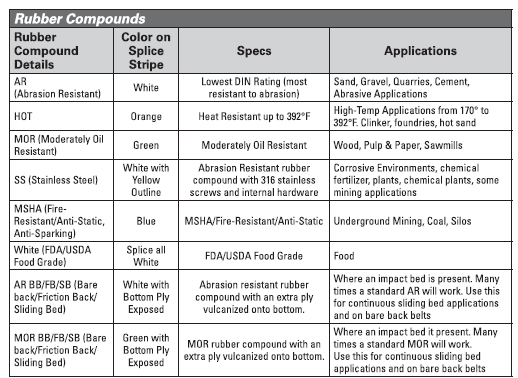

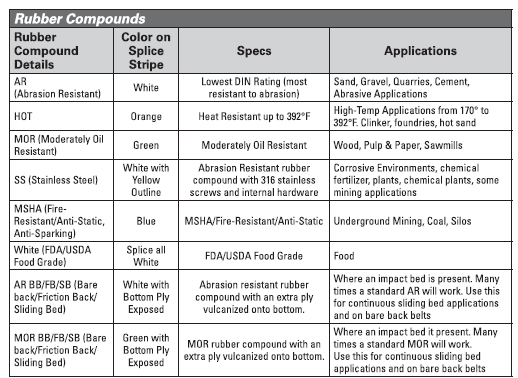

Select Rubber Compound

Fastener Selection Guidelines

Specify the Correct Super-Screw® Flexible Rubber Splice ‘The four items needed to order a Super-Screw splice are below. ‘The complete part number will be in this order: “A-B-C-D”

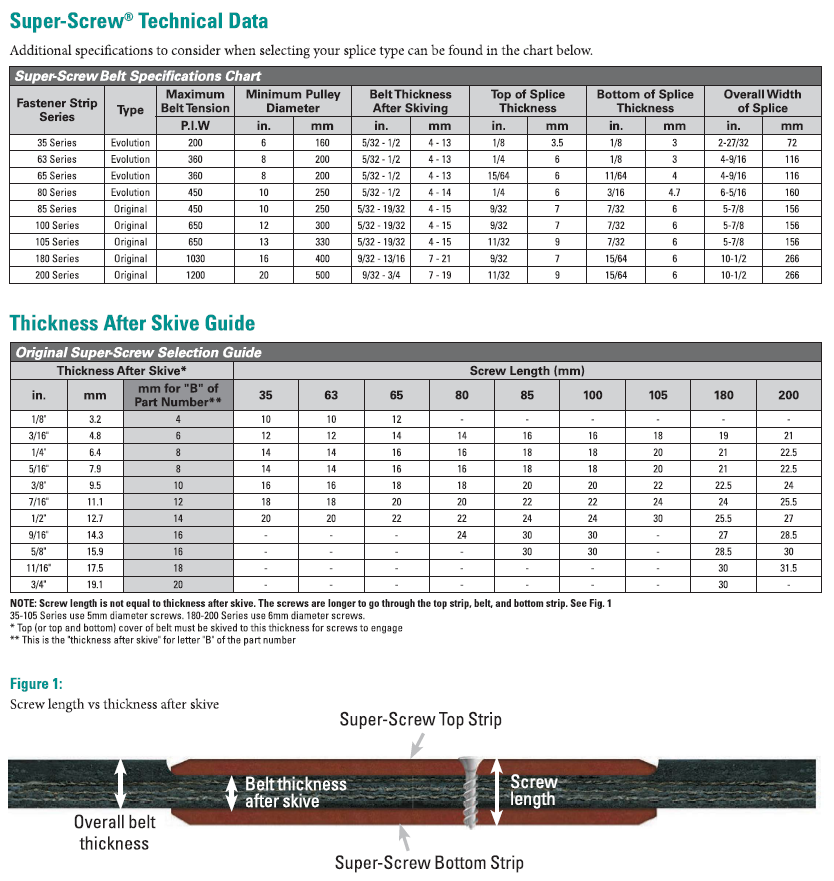

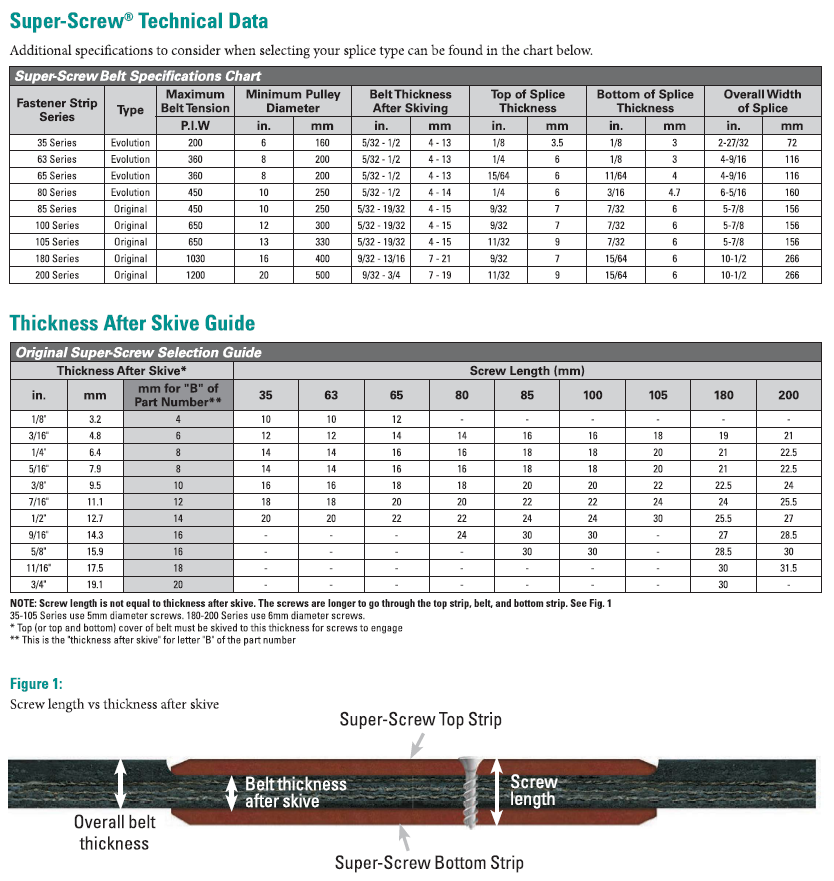

A. Determine the belt tension rating and measure the smallest pulley in your system. This determines the series to use.

Most conveyor belting has a mechanical fastener rating. Care should be taken not to operate the belting or fasteners beyond their recommended rating. Refer to page 4 for a chart listing the recommended maximum tension for each series. Consider pulleys over which the belt makes at least a 90-degree wrap. For tail or take-up of the self-cleaning “wing type” pulley, 25% larger diameter dimensions are usually required. Refer to the Super-Screw Series Technical Data chart on page 5 for selecting the appropriate series based on the PIW and minimum pulley diameter.

B. Measure belt thickness after skiving. This determines the screw length needed.

Measure the thickness of the belt after skiving by subtracting the top cover thickness from the overall belt thickness, or by measuring from the bottom ofthe belt to the top of the top ply. Refer to the Thickness After Skive guide on page 5 to find the “mm rounded up” number.

C. Choose the Super-Screw Splice length.

Super-Screw* Evolution has an 18° bias installation requirement, so splices must be ordered wider than belt width. The formula for length to order Evolution is (Belt Width) x (1.067) then round down to the nearest inch.

Super-Screw* Original has a 5° bias installation requirement, so splice length required is equal to belt width (example: order a 36″ splice for a 36″ wide belt). You can also refer to the Splice Width Selection Guide on page 6 for total splice length needed for common belt widths.

D. Select the rubber compound best suited for the application. This determines the type of rubber for the splice.

Super-Screw® Splice Selection

Use the chart below to determine which Super-Screw® fastener series and screw length to use.

Additional Super-Screw® Selection Guidelines

The following tools are needed to properly splice a belt using the Super-Screw Flexible Rubber Fastening System:

- Super-Screw Fastener Strips

- Screws*

- Assembly Spacers

- Powered drill or 1/4″ impact driver

- PZ bit

- Belt Skiver

- Belt Marking Pen

- Tape Measure

- Belt or Carpenter Square

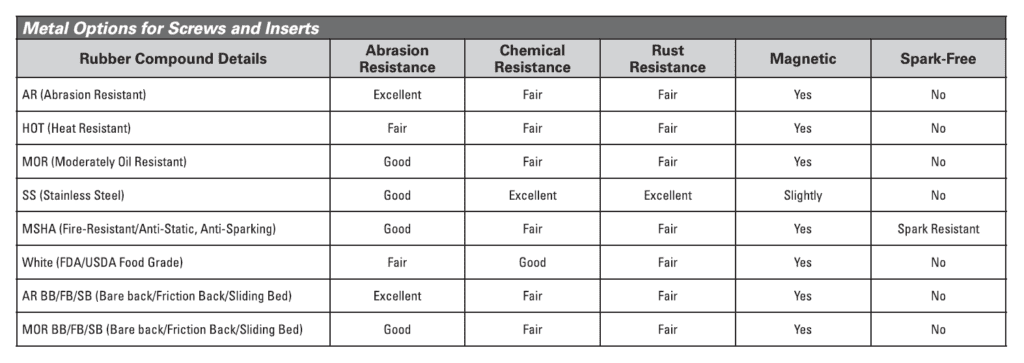

Super-Screw® Metal Options for Screws and Inserts

The Super-Screw® Flexible Rubber Fastening System features to different metal options of screws and inserts.

Galvanized: Galvanized steel is the standard fastener material for most applications. Galvanization helps combat mild corrosion.

Stainless: 316 Stainless steel provides extra resistance to magnetic attraction and corrosion from acids and other chemicals.

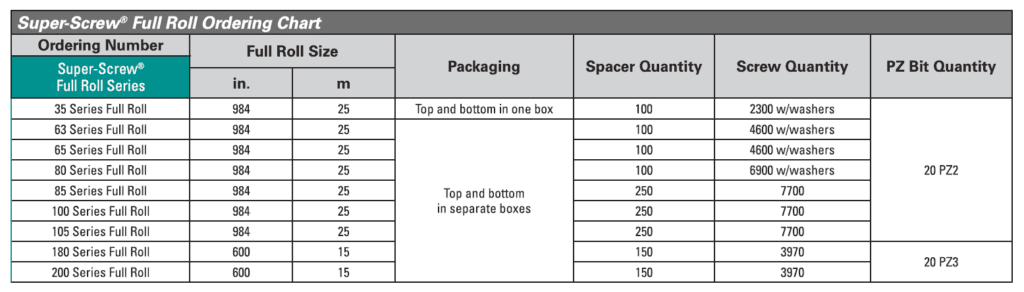

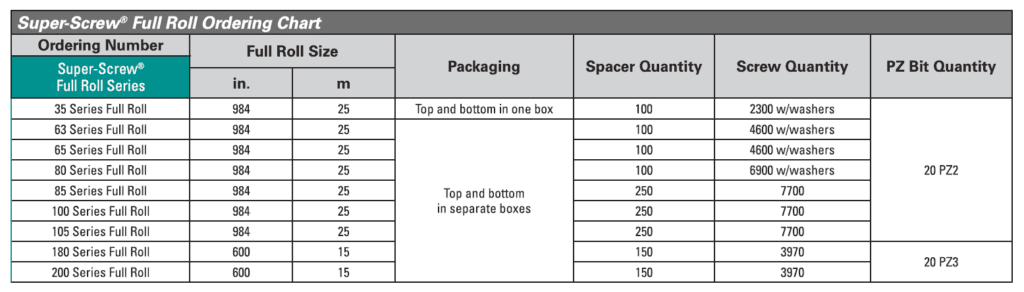

Super-Screw® Full Roll Ordering

When ordering a full roll, different screw lengths can be specified as needed in any quantity. Total screw quantity for a full roll of each series is listed below.

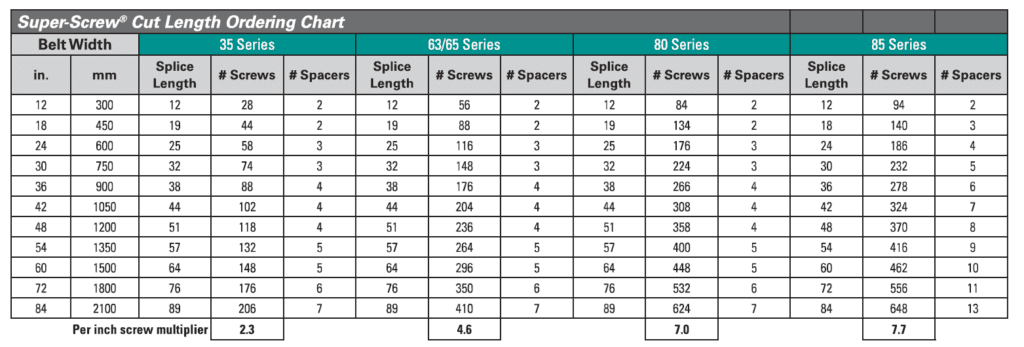

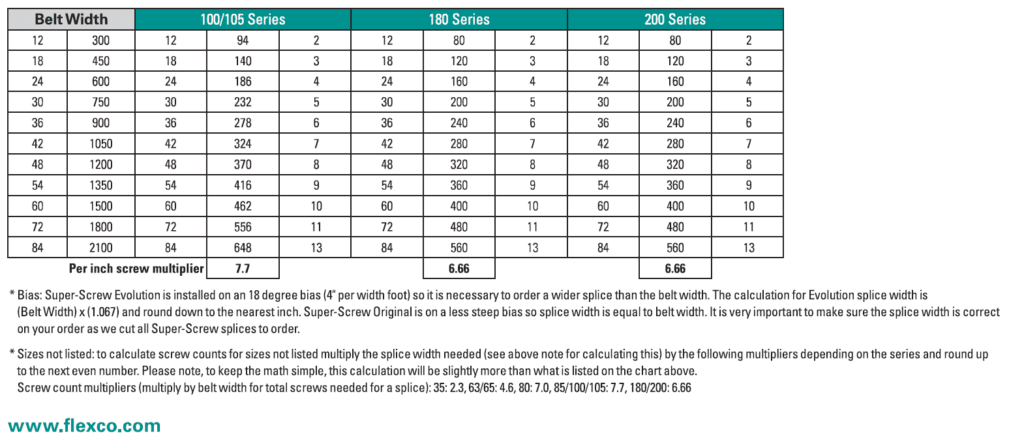

Super-Screw® Cut Length Ordering

Ready to install cut lengths are also available and are delivered with the appropriate number of screws and PZ bits to install the splice.

When ordering a cut-to-length splice, the four items on page 3 are required: Super-Screw Series, belt thickness after skive, splice length, and rubber compound. Total screw and spacer quantity for common sizes is below.